|

OFENBAU FRITZ |

|

OFENBAU FRITZ supplies annealing plants for fine wires, stripes, profiles and tubes of low carbon steel, copper, alumina and alloys since 1947. Annealing under vacuum, partial vacuum, protective gas atmosphere or protective gas circulation (compression annealing).

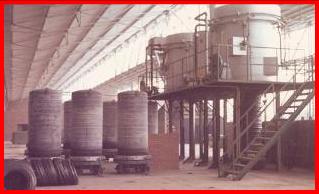

Thanks to the light construction of our hood annealing furnaces, modern plants have stationary annealing pots, with the furnace being comfortably moved by crane from one annealing place to the next. Depending on charge weight, cooling time etc., 4 – 6 annealing pots are usually necessary for continuous annealing, though small plants with a low output need less annealing pots. The cooling times can be reduced by using a cooling belt, which is placed over the annealing hoods.

The coils are piled on the solid table plate of the annealing base and the hood is placed over it. The annealing hoods are vacuum-tight, to avoid an oxidation of the metal during cooling. The sealing of the annealing pot is done with a massive, water-cooled rubber packing ring (invention and patent OFENBAU FRITZ). The pot is evacuated (vacuum pump) and, depending on the annealing procedure, filled with protective gas or left with vacuum. During the heating, an overpressure is created in the pot, which is allowed to escape through a special overpressure valve. Nearly all metals can be bright annealed under vacuum (naturally the wire must be bright at entering the pot, the annealing is not a cleaning process). With protective gas atmosphere, the heat transmission is more effective and the output higher.

We apply the compression annealing since 1968, where the protective gas in the pot is circulated at high speeds by a special, heat-resistant and vacuum tight circulation fan. The construction of the annealing bases is more sophisticated, but the compression annealing has many advantages despite the higher price:

● high quality and uniformity of the annealed wire ● excellent heat transfer thanks to the protective gas circulation ● annealing and cooling times are reduced by ~100% ● the output is doubled compared to vacuum annealing ● the number of annealing pots required is reduced to about half ● with shorter annealing times, the energy consumption of the furnace is reduced |

|

ANNEALING PLANTS |