|

OFENBAU FRITZ |

|

OFENBAU FRITZ supplies bell-type annealing furnaces since 1947. In modern plants, the annealing pots are stationary and the furnace is moved by crane from one annealing place to the next. This is made possible by the very low weight of our furnaces (1.0 Ė 2.5t for small to medium-sized furnaces), achieved by lining the furnace with special ceramic fibre instead of heavy refractory lining. For hood annealing furnaces, electric heating is to be preferred, since the consumption of energy is significantly lower and the distribution of heat within the furnace is very uniform.

The advantages of a transportable furnace are: ● all connections to the annealing places are fixed (water, vacuum, protective gas)† ● the hot annealing pots donít have to be moved ● no need for wheels on the annealing base ● no rail system, no shifting car necessary ● neither an elevating piston nor a lowering platform are needed ● all these factors result in a considerable price and operation advantage

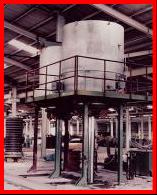

The furnace construction is the same no matter what annealing process is applied, only the construction of the annealing base is more sophisticated for the compression annealing, which circulates the protective gas. The steel construction and the lining of the furnace are so simple that the assembly can be wholly done by the customer according to our detailed instructions. OFENBAU FRITZ manufactures hood annealing furnaces both transportable and raised on columns. We can also adapt the construction of our furnaces to other existing annealing pots (of the competition) and have converted stationary (old-fashioned) furnaces to our system. |

|

BELL ANNEALING FURNACES |